AI Video Analytics Software for Manufacturing & Factories

The Rise of the AI Smart Factory

Factories are no longer just about machines and manual supervision. With AI video analytics for factories, manufacturers are transforming into AI smart factories that combine automation, intelligence, and real-time monitoring. By using artificial intelligence factory solutions, businesses can improve quality control, prevent downtime, enforce safety compliance, and streamline workflows.

Unlike traditional CCTV surveillance that only records incidents, AI solutions for manufacturing actively analyze live video feeds to detect product defects, monitor equipment health, and flag safety risks. This makes modern factories more efficient, safer, and future-ready, all while leveraging existing camera infrastructure.

Highlights

- Connect upto 8 Camera Channels

- Upto 2 Use-cases per Camera*

- Interactive Dashboard

- Automated Reports

- 12 Months Remort Support*

Minimum Hardware requirements*

Processor: Core i7 11th Gen or above

Storage: 1TB

Memory: 32 GB RAM, 4 GB NVIDIA Graphics card

OS: Windows 64-bit

- Hardware requirements may vary upon technical assessment*

- Automatic number plate recognition can be an odd-on at additional cost*

Why Factories Need Advanced Video Analytics?

Manufacturing today is more demanding than ever: quality, safety, compliance, and efficiency all matter. Traditional methods struggle with manual inspections, delayed defect detection, and safety incidents. A smart factory driven by AI video analytics for factories changes that.

With AI solutions for manufacturing and ai in industrial automation, you can:

- Monitor every machine, person & process in real time

- Detect anomalies & product defects instantaneously

- Improve safety compliance, reduce risk, and enforce protocols automatically

- Drive up production throughput while reducing waste and downtime

Key Features & Benefits

| Feature | How It Helps |

|---|---|

| Defect Detection & Quality Control | AI models inspect production lines continuously, flag defects, missing parts, faulty assembly, wrong labelling. Improves product consistency and reduces returns. |

| Machine/Equipment Anomaly Alerts | Detect overheating, unusual vibrations, abnormal behaviour — enabling preventive maintenance, avoiding breakdowns. |

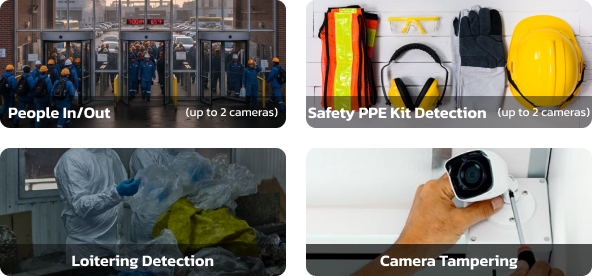

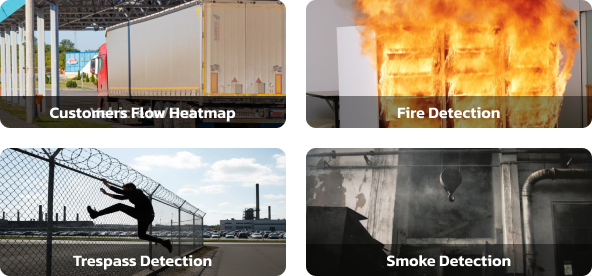

| Safety & Behavior Monitoring | Enforce safety gear (PPE), detect unsafe zones, unauthorized access, and intrusions. Helps avoid accidents and regulatory issues. |

| Real-Time Dashboard & Analytics | Get visibility over cycle times, bottlenecks, downtime, idle machines. Use data to optimize workflows and resource allocation. |

| Enhanced Operational Automation | Automated workflows: camera triggers, alert escalation, integration with Manufacturing Execution Systems (MES) or ERP; helps in smart scheduling and smart factory CCTV analytics. |

Real-World Use Cases

| Use Case | Problem Solved | Impact |

|---|---|---|

| Production Defect Detection | Manual inspection misses small defects; high reject rates | Early defect detection lowers waste, reduces rework, raises yield and quality metrics. |

| Safety Violation & Hazard Detection | PPE non-compliance, forbidden access, unsafe machine usage | Improved safety, fewer accidents, lower insurance & compliance risk. |

| Machine Downtime Monitoring | Sudden failures lead to unplanned downtime and production loss | Predictive alerts enable scheduling maintenance, reducing unplanned downtime. |

| Process Bottleneck Identification | Certain stages in assembly line slow others, but no easy visualization | Dashboards + analytics reveal bottlenecks; process can be rebalanced. |

Why Choose Our Video Analytics Solution for Smart Factory?

- Camera-Agnostic Integration: Works with your existing CCTV/IP camera network; no need for full hardware overhaul.

- AI Solutions for Manufacturing: Tailored AI video analytics to suit factory environments, lighting, and operations.

- Scalable Architecture: From one production line to multiple factory sites. Scalable cloud or edge deployment.

- Real-Time Alerts & Monitoring: Instant notifications of safety events, defects, and intrusions. Live dashboards for management.

- Industrial Automation & Factory Compliance: Enforce safety gear, track SOP compliance. Integrate with MES/ERP systems.

- Proven Accuracy & Support: Calibrated models for Indian conditions; ongoing support, training, and false alarm tuning.

Implementation Process

- Audit & Site Survey: Lighting, camera angles, blind spots, and environmental factors are assessed.

- Installation & Integration: Integrate with existing CCTV/IP systems, set up relevant zones, and define detection rules for manufacturing defects, safety zones.

- Model Training & Calibration: Training AI models on factory-specific data (defects, machine faults, operator behaviour) to reduce false positives.

- Live Monitoring & Dashboarding: Real-time dashboards for production, safety & quality metrics.

- Continuous Optimization & Feedback: Use data to iteratively improve layout, workflow, safety protocols, and respond to model feedback.

FAQ’s About Smart Factory Video Analytics Software

CCTV records events; AI video analytics turns that recorded (or live) video into actionable intelligence: automatically detecting defects, safety violations, machine anomalies, intrusion, etc., often in real time.

No, our solution works with standard CCTV/IP cameras. Better quality (higher resolution, consistent lighting) improves detection, particularly for defect detection, but not mandatory.

Yes. Many Indian manufacturers are adopting industrial automation and integrating AI-based video analytics. Government initiatives, Industry 4.0 push, and competitor solutions (e.g., from Quytech, ATSS) show strong momentum.

Automotive components, FMCG & packaging, electronics manufacturing, chemical/pharma, industrial parts, any factory with frequent defects, safety risks, or heavy regulatory compliance needs.